Navy Electricity and Electronics Training Series, NAVEDTRA 14176

|

MIL-W-22759 |

||||||||||||||

|

M22759 |

/16 |

- |

22 |

- |

9 |

Example: 22 gauge white aircraft wire |

||||||||

|

(1) |

(2) |

(3) |

(4) |

|||||||||||

|

(1) |

Base P/N |

|||||||||||||

|

(2) |

Specification Sheet |

|||||||||||||

|

(3) |

Conductor Size |

|||||||||||||

|

(4) |

Insulation Color |

|||||||||||||

|

(2) SPECIFICATION SHEET SUMMARY |

||||||||||||||

|

SPEC |

INSULATION TYPE |

CONDUCTOR TYPE |

VOLTAGE |

TEMP |

M27500 |

|||||||||

|

RATING |

RATING |

TYPE |

||||||||||||

|

/5 |

Extruded Mineral Filled PTFE |

Silver Plated Copper |

600 Volts |

200°C |

VA |

|||||||||

|

/6 |

Extruded Mineral Filled PTFE |

Nickel Plated Copper |

600 Volts |

260°C |

WA |

|||||||||

|

/7 |

Extruded Mineral Filled PTFE |

Silver Plated Copper |

600 Volts |

200°C |

SA |

|||||||||

|

/8 |

Extruded Mineral Filled PTFE |

Nickel Plated Copper |

600 Volts |

260°C |

TA |

|||||||||

|

/9 |

Extruded PTFE (teflon) |

Silver Plated Copper |

1000 Volts |

200°C |

LE |

|||||||||

|

/10 |

Extruded PTFE (teflon) |

Nickel Plated Copper |

1000 Volts |

260°C |

LH |

|||||||||

|

/11 |

Extruded PTFE (teflon) |

Silver Plated Copper |

600 Volts |

200°C |

RC |

|||||||||

|

/12 |

Extruded PTFE (teflon) |

Nickel Plated Copper |

600 Volts |

260°C |

RE |

|||||||||

|

/16 |

Extruded ETFE (tefzel) |

Tin Plated Copper |

600 Volts |

150°C |

TE |

|||||||||

|

/17 |

Extruded ETFE (tefzel) |

Silver Plated High Strength Copper Alloy |

600 Volts |

150°C |

TF |

|||||||||

|

/18 |

Extruded ETFE (tefzel) |

Tin Plated Copper |

600 Volts |

150°C |

TG |

|||||||||

|

/19 |

Extruded ETFE (tefzel) |

Silver Plated High Strength Copper Alloy |

600 Volts |

150°C |

TH |

|||||||||

|

/20 |

Extruded PTFE (teflon) |

Silver Plated High Strength Copper Alloy |

1000 Volts |

200°C |

TK |

|||||||||

|

/21 |

Extruded PTFE (teflon) |

Nickel Plated High Strength Copper Alloy |

1000 Volts |

260°C |

TL |

|||||||||

|

/22 |

Extruded PTFE (teflon) |

Silver Plated High Strength Copper Alloy |

600 Volts |

200°C |

TM |

|||||||||

|

/23 |

Extruded PTFE (teflon) |

Nickel Plated High Strength Copper Alloy |

600 Volts |

260°C |

TN |

|||||||||

|

/28 |

Extruded PTFE w/ polymide hardcoat |

Silver Plated Copper |

600 Volts |

200°C |

JB |

|||||||||

|

/29 |

Extruded PTFE w/ polymide hardcoat |

Nickel Plated Copper |

600 Volts |

260°C |

JC |

|||||||||

|

/30 |

Extruded PTFE w/ polymide hardcoat |

Silver Plated High Strength Copper Alloy |

600 Volts |

200°C |

JD |

|||||||||

|

/31 |

Extruded PTFE w/ polymide hardcoat |

Nickel Plated High Strength Copper Alloy |

600 Volts |

260°C |

JE |

|||||||||

|

/32 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

/33 |

Crosslinked ETFE (tefzel) |

Silver Plated High Strength Copper Alloy |

600 Volts |

200°C |

|

|||||||||

|

/44 |

Crosslinked ETFE (tefzel) |

Silver Coated Copper |

600 Volts |

200°C |

|

|||||||||

|

(3) Conductor |

||||||||||||||

|

Size |

||||||||||||||

|

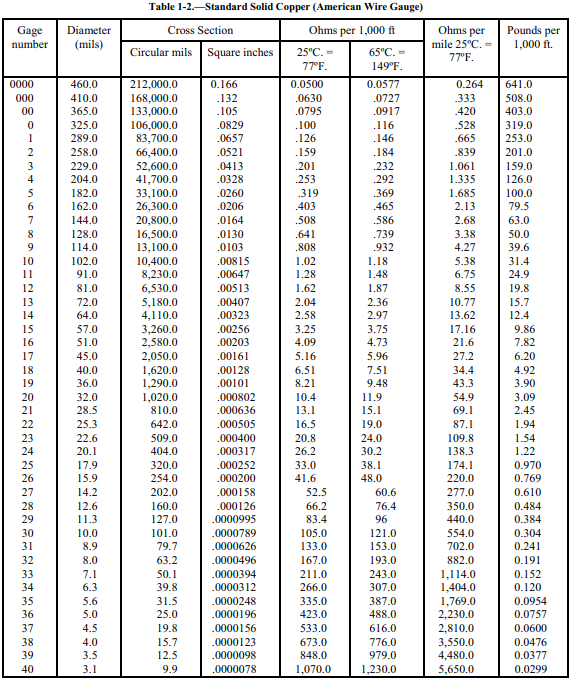

American Wire Gauge (AWG) wire size |

||||||||||||||

|

(4) Color |

||||||||||||||

|

Code |

COLOR |

|||||||||||||

|

0 |

black |

|||||||||||||

|

1 |

brown |

|||||||||||||

|

2 |

red |

|||||||||||||

|

3 |

orange |

|||||||||||||

|

4 |

yellow |

|||||||||||||

|

5 |

blue |

|||||||||||||

|

6 |

green |

|||||||||||||

|

7 |

purple |

|||||||||||||

|

8 |

gray |

|||||||||||||

|

9 |

white |

|||||||||||||

|

Specificaiton MIL-W-27500 |

|||||||

|

M27500 |

- |

20 |

SB |

3 |

T |

23 |

|

|

(1) |

(2) |

(3) |

(4) |

(5) |

(6) |

(7) |

|

|

(1) |

Base P/N |

||||||

|

(2) |

Color Coding and Shielding Coverage |

||||||

|

(3) |

Conductor Size (AWG) |

||||||

|

(4) |

Base Specification |

||||||

|

(5) |

Number of Conductors |

||||||

|

(6) |

Shield Type |

||||||

|

(7) |

Outer Jacket |

||||||

|

(3) Conductor |

|||||||

|

Size |

|||||||

|

American Wire Gauge (AWG) wire size |

|||||||

|

(4) Base Specification |

|||||||

|

|

|||||||

|

See M22759 for common specificaitons |

|||||||

|

COAX CABLE |

||||||||

|

# |

Z |

Attn. / 100' (dB) |

Velocity |

Dielectric |

VMAX |

OD |

||

|

|

(ohm) |

@ 500 MHz |

@ 1 GHz |

% |

Material |

(rms Kv) |

(in) |

|

|

RG6U |

75 |

1.5 |

11 |

78 |

FPE |

0.6 |

0.270 |

|

|

RG8U |

52 |

1.2 |

9 |

66 |

PE |

5 |

0.405 |

|

|

RG8U |

50 |

1.1 |

|

78 |

PE |

0.6 |

0.405 |

|

|

RG8X |

50 |

|

13.5 |

|

|

2.5 |

|

|

|

RG11U |

75 |

1.3 |

9 |

66 |

PE |

5 |

0.405 |

|

|

RG11U |

75 |

1 |

|

78 |

foam |

0.6 |

0.405 |

|

|

RG55B/U |

53.5 |

|

16.5 |

|

|

1.9 |

0.206 |

|

|

RG58U |

53 |

3.1 |

20 |

66 |

PE |

1.9 |

0.195 |

|

|

RG58U |

50 |

3.2 |

|

78 |

foam |

0.2 |

0.195 |

|

|

RG59U |

73 |

2.4 |

11.5 |

66 |

PE |

2 |

0.242 |

|

|

RG62U |

93 |

1.9 |

8.5 |

8 |

air/PE |

0.7 |

0.140 |

|

|

GR59U |

75 |

2.1 |

|

78 |

foam |

0.3 |

0.242 |

|

|

RG71U |

93 |

1.9 |

8.5 |

84 |

air/PE |

0.7 |

0.250 |

|

|

RG108A/U |

78 |

|

26.2 |

|

|

1 |

|

|

|

RG122U |

50 |

4.5 |

29.2 |

66 |

PE |

1.9 |

|

|

|

RG140U |

75 |

|

13 |

|

|

2.3 |

|

|

|

RG141U |

50 |

2.1 |

13 |

69 |

teflon |

1.9 |

|

|

|

RG142U |

50 |

2.7 |

13 |

69 |

teflon |

1.9 |

0.159 |

|

|

RG178U |

50 |

10.5 |

45 |

69 |

teflon |

1 |

0.071 |

|

|

RG179U |

75 |

8.5 |

25 |

69 |

teflon |

1.2 |

0.100 |

|

|

RG180U |

95 |

4.6 |

16.5 |

69 |

teflon |

1.5 |

0.140 |

|

|

RG187U |

75 |

8.5 |

25 |

69 |

teflon |

1.2 |

0.105 |

|

|

RG188U |

50 |

9.6 |

30 |

69 |

teflon |

1.2 |

0.106 |

|

|

RG196U |

50 |

10.5 |

45 |

69 |

teflon |

1.2 |

0.076 |

|

|

RG303U |

50 |

2.1 |

13 |

69 |

teflon |

1.9 |

|

|

|

RG302U |

75 |

|

13 |

|

|

2.3 |

|

|

|

RG316U |

50 |

9.4 |

30 |

69 |

teflon |

1.2 |

0.098 |

|

|

RG393U |

50 |

|

7.5 |

|

|

5 |

0.390 |

|

|

RG400U |

50 |

|

13 |

|

|

1.9 |

|

|

|

RG401U |

50 |

|

7.5 |

|

semi rigid |

3 |

|

|

|

RG402U |

50 |

|

13 |

|

semi rigid |

2.5 |

|

|

|

RG405U |

50 |

|

22 |

|

semi rigid |

2 |

|

|

|

RG174U |

50 |

6.6 |

31 |

66 |

PE |

1.5 |

0.100 |

|

|

RG210U |

93 |

|

3.1 |

|

|

0.75 |

|

|

|

RG213U |

50 |

1.6 |

9 |

66 |

PE |

5 |

0.405 |

|

|

RG214U |

50 |

1.6 |

9 |

66 |

PE |

5 |

0.425 |

|

|

RG217U |

50 |

|

5.8 |

|

|

7 |

0.545 |

|

|

RG218U |

50 |

|

3.8 |

|

1 |

1 |

|

|

|

RG219U |

50 |

|

3.8 |

|

1 |

1 |

|

|

|

RG223U |

50 |

3.1 |

16.5 |

66 |

1 |

1.9 |

0.212 |

|

|

RG225U |

50 |

|

7.5 |

|

|

5 |

|

|

|

RG9U |

51 |

1.6 |

|

66 |

1 |

5 |

|

|

|

Ethernet |

50 |

1.2 |

|

78 |

foam |

0.6 |

|

|

|

22B/U |

95 tw pr. |

2.1 |

|

66 |

PE |

|

|

|

|

twin lead |

300 |

0.8 - worse when wet |

80 |

PE |

|

|

||

|

8281 |

75 |

|

9.2 |

|

|

2.9 |

|

|

|

9913 |

50 |

|

4.5 |

|

|

0.6 |

|

|

|

9914 |

50 |

|

6 |

|

|

0.6 |

|

|

|

8218 |

75 |

|

20 |

|

|

0.6 |

|

|

Wire Insulation

|

Type |

Trade Name |

Name |

Comments |

Min. T (°C) |

Max. T (°C) |

Abrasion |

Flexibility |

Moisture |

Flammability |

Outgassing |

Weight |

Radiation |

Cold Flow |

Dielectric constant |

|

|

|

|

Silicone Rubber |

Excellent high voltage corona resistance |

-55 |

200 |

Poor |

Excellent |

|

Poor |

Poor |

|

Good |

Good |

|

|

|

PVC |

|

Polyvinyl chloride |

Low cost |

-29 |

105 |

Good |

Good |

Fair |

Good |

|

|

|

|

|

|

|

ETFE |

Tefzel |

Ethylene Tetrafluoroethylene |

Other Brand Names: Fluon by Asahi Glass Company , Neoflon ETFE by Daikin,and Texlon by Vector Foiltec. |

-100 |

150 |

Fair |

Good |

Good |

Fair |

Good |

|

1e6 |

Fair |

|

|

|

Crosslinked ETFE |

Tefzel |

Ethylene Tetrafluoroethylene |

Better abrasion resistance than ETFE, but not quight as good of thermal |

|

200 |

Good |

Fair |

|

Fair |

Good |

|

5e7 |

Good |

|

|

|

|

PTFE |

Teflon |

Polytetrafluoroethylene |

TeflonŽ is DuPont's trademark for its family of fluoropolymer resins which includes PTFE, FEP and PFA. The name is sometimes erroneously used to denote PTFE only. |

-190 |

260 |

Poor |

Excellent |

Good |

Excellent |

Good |

Poor |

5e5 |

Poor |

|

|

FEP |

Teflon |

Fluorinated ethylene propylene |

-100 |

205 |

Poor |

Excellent |

Good |

Excellent |

Good |

Poor |

5e5 |

Poor |

|

||

|

PFA |

Teflon |

Perfluoroalkoxy |

-190 |

260 |

|

|

|

|

|

|

|

|

|

||

|

TFE |

Teflon |

Extruded Tetrafluoroethylene |

Same as PTFE |

-190 |

260 |

|

|

|

|

|

|

|

|

|

|

|

PE |

|

Polyethylene |

|

|

75 |

|

|

|

|

|

|

|

|

|

|

|

XLPE |

|

Crosslinked Modified Polyethylene |

|

|

125 |

|

|

|

|

|

|

|

|

|

|

|

XLPO |

|

Low Smoke, Crosslinked Polyolefin |

|

|

105 |

|

|

|

|

|

|

|

|

|

|

|

EPDM |

|

Ethylene-Propylene Diene Elastomer |

|

|

125 |

|

|

|

|

|

|

|

|

|

|

|

API |

Kapton |

Aromatic Polyimide |

becomes brittle and cracks easily, prolonged exposure to moisture causes deterioration, susceptible to arc tracking. |

-65 |

200 |

Good |

Poor |

Poor |

|

Good |

Excellent |

5e9 |

Excellent |

|

|

|

Polyamide |

Nylon |

|

Serves as a tough jacket but can absorb moisture |

-40 |

120 |

Excellent |

Poor |

Poor |

Poor |

|

|

|

|

|

End